It’s shop season again. Spent the summer moving to a new house and trying to squeeze in as many rides as possible. Now that things are cooling off, my mind is turning to interesting shop projects.

I found this tricycle for my two year old son Emmett about a month ago. He could not take his eyes off it. Once he climbed aboard, it was a real bear pulling him off. A week later I went back alone and bought it for him. I intend to rebuild it (it was pretty beat) for his upcoming second birthday in November. The shop wanted over $100 for it. I pointed out to him that almost every part of it was damaged beyond being functional. Every bearing was seized or rough, the head tube and fork had an inch of play as the bearings had long ago disappeared. The metal in metal areas was severely beat up and distorted. So I made the case that I am about the only customer that exists for this bike with both the desire and ability to fix it up and put it back into use. He could not argue with that logic and I ended up getting it for $70. After pricing bearings yesterday. . . I still overpaid. I don’t care, though.

The trike is an Anthony Brothers Convert-O-Bike. A little researched showed that they have been making them for over 50 years now. From a sticker on the underside of this one, it appears to be made in 1980, despite the ’50s design cues. If you look at the way the rear wheels attach, you’ll notice a forked connection on the main frame. This allows the rear axle to be replaced by a single wheel, converting the bike to a two-wheeler. Cool! The frame, wheels and most other parts are cast aluminum. Only the handlebars and seat post are steel. The grips are the only plastic on the whole bike. When I’m done with it, this bike will last for a hundred years and maybe my great grandkids will ride it.

I got down to the shop yesterday afternoon after going for a nice Fall motorcycle ride. It was a little tougher to get apart than I expected and damaged far more than I originally realized. It’s entirely disassembled, cleaned and inspected now. I have the various bearings on order. I still need to figure out how to bush/bearing the steering tube as the dimensions do not support the use of conventional ball bearings and I am unaware of how it was originally constructed. I think I’m going to make up some bronze bushings with thrust washers. We’ll see.

Pics of the break-down follow.

I can’t wait to see Emmett’s face when I give it to him.

Happy Fall,

Jason

Front end parts. The cranks were screwed on and welded. They needed to be cut to be removed. I was careful to leave enough metal on the spindle and cranks for reuse.

Close-up of front axle and cranks. The cranks are significantly bent and twisted. I’ll likely weld the ends to the edge of welding table and bend back straight.

The fork stem is worn almost entirely through from having been run without a bearing for so long. I’ll have to weld this up and reshape. Also considering just making a new stem and pressing into fork casting if necessary.

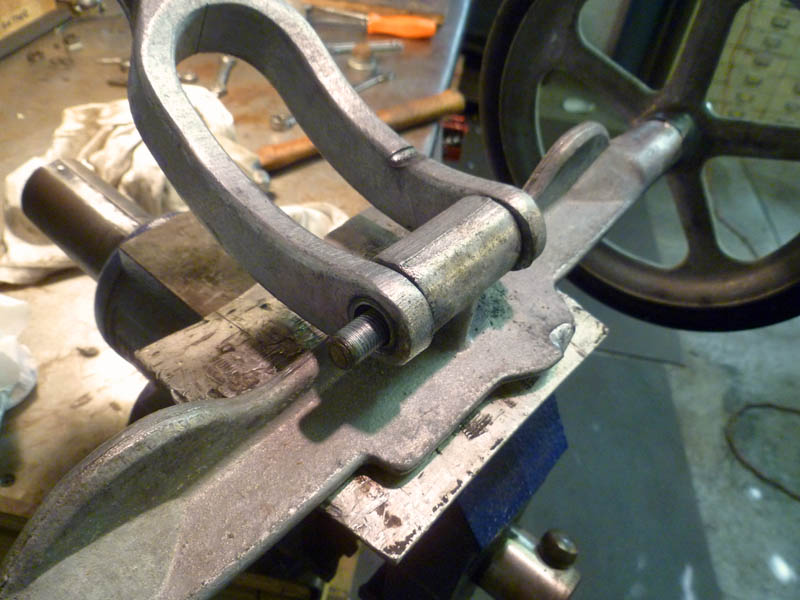

The rear pivot bolt was really stuck in place. Repeated hits with a big sledge hammer yielded no movement.

After heating with the torch, the bolt was much more compliant to gentle persuasion from the sledge hammer. All fixed.

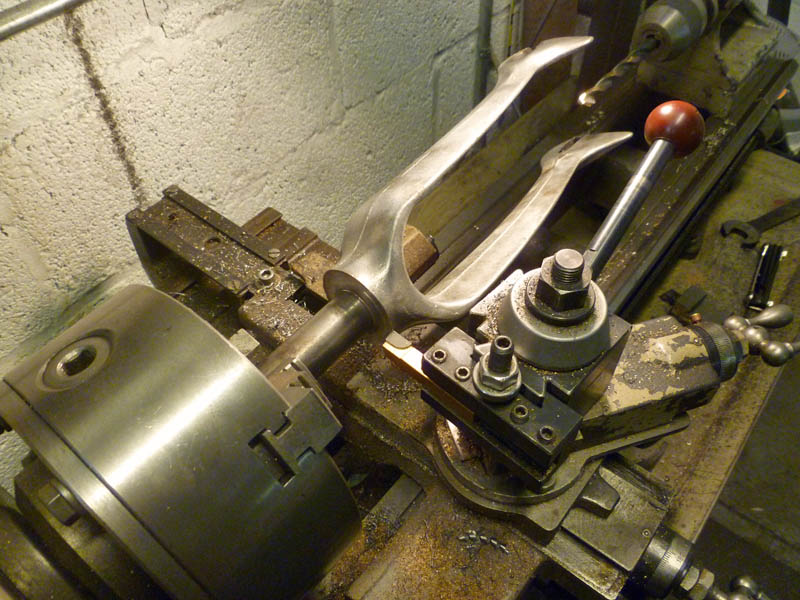

It’s not a proper project if I can’t throw at least some of it in the lathe. The fork crown was deformed from not having a bearing.

Fork crown looks like new. The lower part of the stem will also need to be welded in and reshaped to fill wear.

That is going to be a beautiful trike man. Great style and shape to the parts. It will be the smoothest running tricycle around. your boy will be the king of the sidewalk. Hope all is well man. Worked in Greenpoint a good part of the summer, building sets for NBC studio. Good $, crazy commute. Sounds like your summer was busy for sure. See you in the not to distant future.

Ken

The king!

I like Greenpoint. Megan and I were up there with Emmett a few weeks ago.

Will make a point of getting together this fall.

Jason

Fucking price of bearings will put ya in da powr house!!

Lidl E gonna remember this b-day.This project will bring a smile to your face EVERY time you work or ponder on it. Gonna polish it up ?

Got no time in life for appearances. Gonna be like my bikes: mechanically flawless, but looking like they get used. Plus, he’ll likely leave it in the back yard anyway.

guess it’s beeen awhile! you speak as if i dont know The Mac……sarcasm is a hard read in print.

carry on

It is! Notice I finally fixed the comments feature on this blog? It now actually emails when people reply to comments. Yay.

Looks great. I’m sure it’s done by now. I picked up a trike and a bike. Both need headset bearings. How did you separate it? I tried torch and hammer with no luck.

Funny you should bring up kids bikes,a friend of mine just gave me a springer front end from an schwinn apple crate. just as I’m taking apart a girder front end for chroming,I saw that and told him I’m throwing it in w/the girder. My kids eyes were HUGE when they saw that. “DADDY IT LOOKS JUST LIKE YOURS. CAN YOU MAKE OURS A CHOPPER !?! So when it comes back I’m gonna see if a friend can rake my older ones bike and use a smaller front tire from his old one. The springer still has it’s bearings ,crown nut, and looks as if it’s the same length neck (when I held them up tgo each other. the only problem is the re-paint,oh wait, I have extra large metalflake and paint left over from my sportster!

ain’t bein’ a dad the best!

Tim

That sound like a great idea. He must be thrilled.

Yes, being a dad is great!

Jason

Pingback: Convert-O-Bike Project (step 2) | GreasyGringo

powdercoat black – then flame paint?

Interesting project Jason, thanks for sharing. That is some old school quality.

Gonna leave it like it is. No real interest in changing the cosmetics. Polishing would look pretty slick, but I can’t fathom the amount of work that’d take. Quality, no doubt. He’ll love it.

I bought 6 Converto trikes for my 6 kids children (17 of them). Two of them have bearings gone on the pedal shaft attached to the forks. In looking at your site, I see that I have to cut the weld off to turn the pedal rods of the shaft. All of them have a wobble where the forks and the handle bars meet (I think it is called the yoke). You talk about a brass bearing of sleeve that you used on yours. Was there suppose to be a ball bearing bearing suppose to be there like most bicycles? If not, where did you get the brass sleeve? Secondly, where did you get the bearings for the pedal shaft?

Thank you,

Ed…

Ah yes, the common handlebar wobble. the original design was to have two metal bearing caps pressed on the steerer tube (one top, one bottom) then also two plastic bushings on the steering tube to take up the slack. Also a thin washer goes on the top and bottom, on top of the caps, to act as a bushing of sorts. You’re gonna have to fabricate parts for now, as the company – Anthony bros. has shuttered the factory, and no one else has taken up the manufacturing. Maybe get a kickstarter…..

Bought a converto trike at scrap yd. Looking for right side crank & pedal? Angeles no longer carrys any parts. Anyone know where i can get them?

just bought a concerto bike for my wife…her mother gave her original bike away when she was a kid…the bike I bought is in excellent shape except for left side crank and pedal were broken apart…can you tell me where to get the missing crank and pedal??? For years she has wished she still had her bike…her father new the owner of the original maker…he was a machinist at mobil oil in Torrance CA

Thank you sincerely

Looking for a pedal crank & pedal for one I dug out of recycling center.

If anyone knows where I can get them please contact me & leave message.

Thanks

Ron

951-269-0032

Are you still interested

The company is out of business now, which totally sucks because I’m in charge of keeping a fleet of these things going at my kid’s preschool. I’ve been doing it for about 8 years now. I don’t know what we’re gonna do when the parts start wearing out. I can’t find replacements anywhere. And I’ve looked a ton. I guess the nest step is to get in touch with some metal fabricators.

Nice project Jason

Thanks!

I just logged in here for the first time in a couple years. Life has been busy. A fleet!!!! Awesome.

Need parts? Gonna have to make them ;-0

Hey, I also have just been put in charge of a fleet of converto’s to keep them running. Can we all collaborate?

Have you started? I like to jump on board

I need to do 5 trikes for a preschool, will need all the same parts as you, would love to collaborate. Pinning down sizes and having them made in mass sounds wise.

Allan

801-638-0408

I have one from 1984 good shape, no grips, small crack in the seat (don’t know what he was pounding on) that can be hammered back and filled. I can send pics.

Let me know if interested.

JG

Small world. Just met you this weekend at NJMP where I bought a Convert-O-Bike from my buddy. Found your site while searching for the one part I need, a rear wheel. I’m the guy that was at the end of the row in the little ’66 canned ham camper. Any leads on a nice wheel?

-Thom

I moved to California just days after meeting you. NJMP was cool, first and last time I’ve been there. Hanging out with my riding buddy Dan before skipping town. No idea on parts. I just found this one and fixed it up. Don’t really know much else about them.

Love this site….learned a bunch about these trikes.

For those who are interested we just came across a number of Convert-O tricycles and bicycles as well as parts that we are going to offer up on eBay. We just have to double check to see if there are date stamps on these but we believe they are pre-1984 models. Used by an elementary school that had a disabled children program. California Education code requires that the items be auctioned off so we cannot accept BIN offers before or during the auction. Just trying to figure out if we will do it piece by piece or one pallet lot,.( I’m leaning towards the pallet lot). 4 bicycles, 3 tricycles, 3 tricycle step plates with wheels attached, 3 tricycle step plates without wheels. So be on the lookout in the next week or so .

-Dan

Just a follow up : Most , but not all, are letter stamped. Estimated dating in 1/4″ letter between 1986 – early 1996..before the letter switched over to 1/8″ size.

Looking for pedal crank & pedal gor Convert O Trike?

Thanks

951-269-0032

Leave message of no answer please

No ideas, Ron. I just straightened and welded the one I had.

Great write-up Jason! I just scored a Lo-Boy that’s in decent condition but it is worn in all of the areas that you mentioned in your article. Thinking it would be fun to outfit the entire thing with quality sealed bearings and fresh bronze bushings!

Great post my friend! As a traditional hotrod builder I was immediately drawn to the Convert-O bike the moment I saw one at a swap meet 10 years ago. It’s cast aluminum frame resembling the front Ibeam axle used from the dawn of the automobile until the first independent suspension designs.

I didn’t have a child at the time but I knew when that day eventually came. He or she would love it. So I ponied up some cash, and brought home a low-boy.. years later I scored a high-boy. I now have a 2 year old daughter. Although her feet don’t reach the pedals yet. She tries almost every day….can’t wait for that day to come

Nice!

I also thought of a solid front axle.

Jason

Question. How did you separate the bars from the forks? My bearings are gone as well

Such an awesome blog but equally cool is the amount of people that love these trikes and want to keep them running. Perhaps we can all collaborate?

Jason, since you fixed the bike are you willing to fix others?

This string spans years, there seems to be ongoing need, currently, who needs what? Did all the parts sell on ebay (looking for more)? Anybody parting out partial trikes? I need to rebuild 5 units, looking to gang up and work together, if there are any more outstanding projects. Call me if you are still interested

Allan

801-638-0408

What did you do for the bearings on this guy? I need new bearings for my son’s lo boy and can’t find them anywhere. Unfortunately I’m not as savvy and don’t know if standard/generic bearings work.

Thanks,

Kosmo

Made oil-lite bronze bushings for the head tube.

Ordered standard ball bearings for the wheels. Don’t the sizes handy but you can measure the axles and bosses to get I.D. and O.D. dimensions.

Jason

Great to see the restoration. I rebuilt this one which I believe is a very eraly example because of the fork neck design

Hey Jason,

Looks like the work you did on the tricycle turned out amazing.

I have just acquired an Anthony Brothers convert o tricycle. It needs front bearings. Where did you get yours? Any idea on size?

I also need original rear tires. Any idea on where I can obtain parts?

Thank you,

Dennis

Hi Dennis,

Just dropped in here for the first time in over year.

I made the fork/head bearings. I bought the wheel bearings from McMaster-Carr. Just measured the I.D. and O.D. They were a standard size, easily obtainable.

No idea on the tires. Mine are pretty old and hard, but still intact. Had they been broken up I don’t know how I would have approached it.

Interested in doing another resto on mine?